Your Guide to the Best Bulk Buying Websites for E-commerce

Feeling stuck? It's a common story for growing brands. You've got a great product and hungry customers, but unreliable inventory and razor-thin margins are holding you back. It feels like hitting a brick wall.

Smart product sourcing is what shatters that wall. It transforms a frustrating cost center into your most powerful tool for profit. Using the right bulk buying websites isn't just about finding a cheaper price—it's about building an e-commerce operation that's built to last and scale.

The Sourcing Shift That Changes Everything

Let's imagine a brand with a viral product that’s always selling out. Every time that "out of stock" notice goes up, it's not just a lost sale; it's a lost customer. Their strategy of placing small, frequent orders with local distributors was not only expensive but simply couldn't keep up with the explosive demand. They were trapped in a cycle of missed opportunities, unable to grow.

The game changed when they made a strategic pivot to bulk buying websites. Instead of scrambling for small, expensive batches, they started sourcing directly from manufacturers and major wholesalers. This wasn't a minor adjustment. It was a complete overhaul of their operations, and it unlocked some serious advantages.

From Scrambling to Strategic

By moving to a bulk purchasing model, the brand saw immediate and powerful changes across the business:

- Costs Plummeted: Their cost of goods sold (COGS) dropped dramatically. Securing larger quantities meant unlocking deep per-unit discounts, which instantly padded the profit margin on every sale.

- Inventory for Big Wins: They could finally launch major marketing campaigns with confidence. With thousands of units ready to go, they could ride a wave of viral demand without worrying about their inventory being wiped out in a day.

- A More Robust Supply Chain: Putting all their eggs in one local distributor's basket was a huge risk. By cultivating relationships with several suppliers from different bulk sites, they built a stable, predictable supply chain that wasn't vulnerable to a single point of failure.

This is the moment sourcing stops being a simple back-office task and becomes a core strategic advantage. It’s the difference between just getting by and actively engineering your business for explosive growth and long-term stability.

To really lay the foundation for profitability, you need to get the strategy right. Mastering this process means digging into the practical tips for buying in bulk for resale that separate the brands that thrive from those that just survive.

That's what this guide is all about. We’ll walk through how to find and vet suppliers, negotiate killer terms, and use real data to make sourcing decisions that pour fuel on your growth, turning your operations from unpredictable to unstoppable.

Decoding the World of Bulk Buying Websites

Diving into bulk buying websites can feel a lot like walking into a massive, sprawling city for the first time. Every neighborhood has its own vibe, its own rules, and its own unique opportunities. To find what you need without getting lost, you need a map. Think of the sourcing world as an ecosystem with four key habitats, each perfectly suited to a different kind of e-commerce business.

Getting a handle on these four core supplier types is the first step toward building a sourcing strategy that’s both resilient and profitable. Each platform is built for a different purpose, and knowing the lay of the land helps you match your sourcing with your product, your business stage, and where you want to go next.

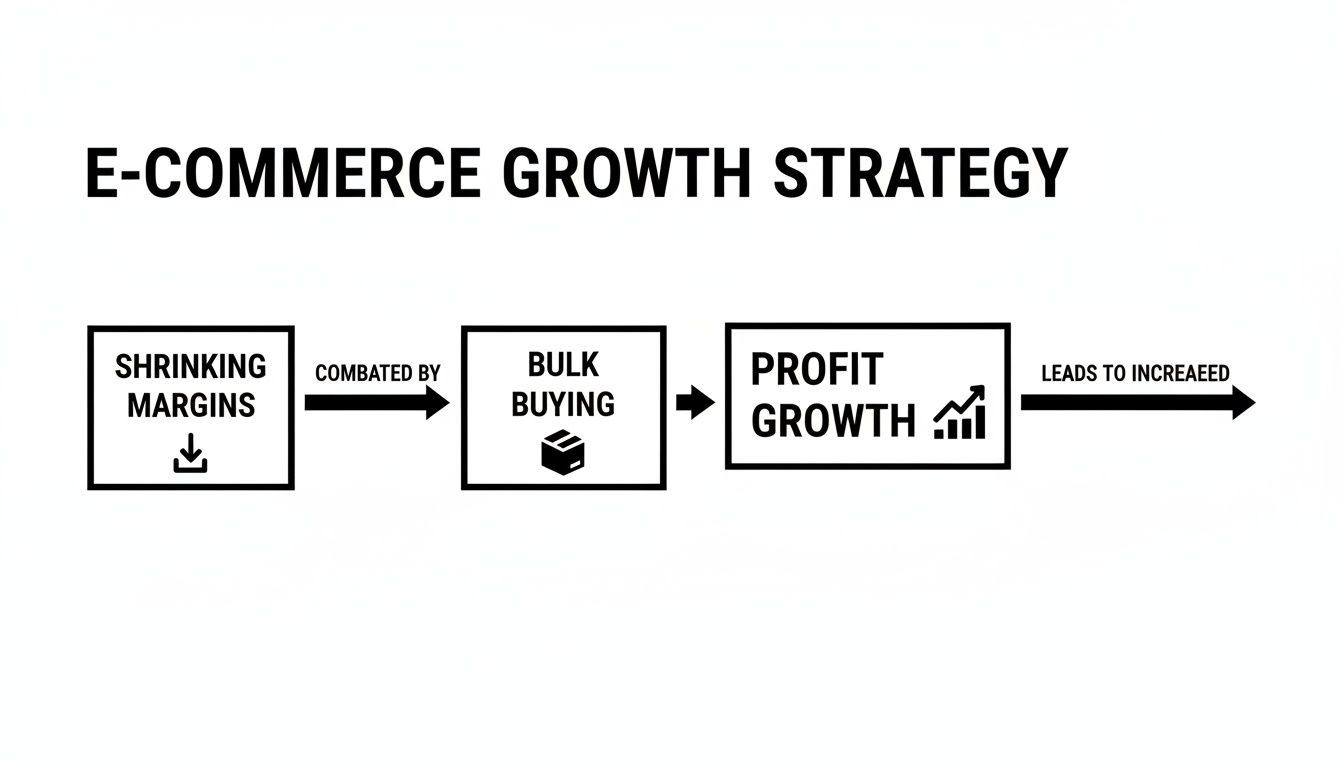

The flowchart below shows exactly how smart bulk buying can be a direct antidote to shrinking margins, paving the way for real growth.

This isn't just a concept; it's a powerful reality for sellers. Actively seeking out bulk purchasing is one of the most direct paths to fattening up your profit margins.

To help you navigate this landscape, let's break down the main types of suppliers you'll encounter on bulk buying websites. This table gives you a quick snapshot of what to expect from each.

Comparing Supplier Types on Bulk Buying Websites

This table provides a quick-glance comparison of the four main types of bulk suppliers, helping business owners decide which platform best fits their needs based on price, order size, product variety, and ideal business model.

| Supplier Type | Typical Pricing | Minimum Order Quantity (MOQ) | Best For | Example Platform |

|---|---|---|---|---|

| Wholesale Marketplace | Low to Moderate | Low to Medium | Businesses needing variety and product discovery | Alibaba |

| Direct from Manufacturer | Lowest | Very High | Established businesses with proven demand and high volume | Direct factory relationships |

| Liquidation Platform | Deeply Discounted | Varies (often by pallet/lot) | Opportunistic sellers and discount retailers | B-Stock |

| B2B Distributor | Moderate | Low to Medium | Niche businesses needing specialized, curated products | Industry-specific suppliers |

Each of these supplier types offers a distinct set of advantages and challenges. The key is to find the one that aligns with your business's capital, storage capacity, and overall market strategy.

Wholesale Marketplaces: The Global Bazaars

Wholesale marketplaces are the giant, bustling bazaars of the internet. Think of sites like Alibaba or Faire—they are massive hubs connecting thousands of different sellers and factories with buyers all over the world. Their claim to fame is an almost bottomless product selection.

It’s like walking through a market where one stall sells handcrafted leather goods, the next sells cutting-edge electronics, and another offers organic spices. That sheer variety is the main draw, making these marketplaces a fantastic starting point for discovering new products or sourcing a wide range of goods.

Direct from Manufacturer: The Source Code

Going direct-from-manufacturer (DFM) is like buying your vegetables straight from the farm instead of the supermarket. You're cutting out all the middlemen—the distributors, the wholesalers—and buying right from the factory that makes the product. This route almost always gets you the lowest possible cost per unit.

But this big advantage comes with a major catch. Manufacturers demand very high Minimum Order Quantities (MOQs). We're talking orders in the thousands, or even tens of thousands, of units at a time. That requires serious upfront cash and the warehouse space to store it all. This path is really for established brands that have predictable, high-volume demand for their products.

Sourcing directly from the manufacturer gives you maximum control over customization and the best unit economics. But it's a high-stakes game reserved for businesses ready to commit to large-volume orders.

Liquidation Platforms: The Treasure Hunt

Liquidation websites are the treasure chests of the sourcing world. Platforms like B-Stock or Liquidation.com are where big retailers offload their overstock, customer returns, and end-of-life inventory. The deals here can be absolutely incredible, often just a fraction of the original wholesale price.

This is an opportunistic game, though. You can't build a consistent, long-term supply chain here because the inventory is completely unpredictable. But for sellers hunting for amazing one-off deals to spike their margins or test new product categories, liquidation sites offer a thrilling hunt for deeply discounted goods. The growth of these platforms is part of a wider trend; B2B e-commerce is expected to hit $36.16 trillion by adopting consumer-style features like easy bulk checkouts. You can find more B2B e-commerce statistics and insights on SellersCommerce.com.

B2B Distributors: The Niche Specialists

Finally, we have B2B distributors—the specialists. They don’t actually make anything themselves. Instead, they buy huge quantities from various manufacturers and then focus on a specific industry or niche. You might find a distributor that only deals in professional-grade salon equipment, or another that specializes in eco-friendly packaging materials.

Distributors offer a curated product selection, deep industry knowledge, and often have much more flexible MOQs than a manufacturer. They are the perfect partners for businesses that need specialized products and want a supplier who truly understands their market. They neatly bridge the gap between massive factory orders and small-batch buying, providing a reliable source for niche players.

How to Vet Suppliers and Avoid Costly Mistakes

Finding a list of potential suppliers on bulk buying websites is the easy part. The real work—and where a lot of businesses stumble—is figuring out which ones are legitimate partners and which ones are a waste of time, or worse, a scam. Think of it like hiring a key employee; you wouldn't just glance at a resume and sign a contract. You need to dig in and do your homework.

If you skip this step, you're opening yourself up to a world of pain: shoddy products, blown deadlines, and even outright fraud. A great starting point is learning how to find wholesale suppliers in the first place. That will give you a solid list of candidates to put through the wringer, which is exactly what we're about to do.

This isn't about just browsing websites. It's about methodically building a supply chain you can count on.

Analyzing Pricing and Your True Landed Cost

That attractive price-per-unit you see on the website? It’s almost never what you'll actually pay. To get a real sense of your profitability, you have to calculate your landed cost. This is the all-in price to get one single unit from their factory door to your warehouse shelf.

Figuring this out is the only way to know your true profit margins. It forces you to look beyond the supplier's quote and account for every expense along the way.

- Cost of Goods Sold (COGS): This is the basic price you pay the supplier for each item.

- Shipping & Freight: The cost to get your order from their location to yours. This can swing wildly depending on if you choose air or sea freight and how far it has to travel.

- Customs & Duties: The taxes and fees your government will charge to import the goods.

- Insurance: Protects you if your shipment gets lost or damaged in transit.

If you don't bake these costs into your numbers, an order that looks profitable on paper can quickly turn into a money-loser. Getting a handle on accounting for manufacturing is a huge help here, as it shows you how all these little costs fit into the bigger financial picture.

Verifying Certifications and Business Legitimacy

Good suppliers are proud of their credentials and have nothing to hide. Checking their business details and quality certifications is a simple, non-negotiable step to protect yourself.

First, look for the basics on their company profile. They should have a verifiable business registration number, a physical address (go ahead, look it up on a map), and a landline phone number. Be suspicious of any supplier who only lists a cell phone or is cagey about where they're actually located.

Next, hunt for certifications related to quality management or specific product standards. These are your proof that a third party has audited their processes and confirmed they meet certain benchmarks.

- ISO 9001: This is the global gold standard for quality management. It means the supplier has reliable systems in place to produce a consistent product.

- CE Marking: If you sell in Europe, this is a must-have. It shows the product meets EU standards for health, safety, and environmental protection.

- FCC Certification: This is required for most electronics sold or made in the U.S. that could cause radio frequency interference.

A supplier with verifiable certifications is signaling that they've invested in their processes and are serious about meeting global standards. Their absence, especially in technical industries, should be considered a significant red flag.

Spotting the Red Flags in Communication

The way a potential supplier communicates with you right at the start is a massive tell. It gives you a sneak peek into how they operate and what it will be like to work with them down the road.

Keep your eyes peeled for these warning signs:

- Vague or Evasive Answers: If you ask about production capacity or material sources and they give you the runaround, it's a bad sign. They're either disorganized or hiding something.

- Poor Communication Skills: Sure, language barriers can be a thing. But if their emails are consistently unprofessional or they keep misunderstanding simple requests, imagine how messy things will get when there’s a real problem.

- High-Pressure Sales Tactics: A good partner wants to build a long-term relationship, not push you into a quick sale. If they're trying to rush you, be wary.

- Unwillingness to Provide Samples: Any supplier who is confident in their product will be happy to send you samples. If they refuse, it’s a giant red flag that their quality isn't what they claim.

Trust your gut. If the conversation feels off from the beginning, it’s not going to magically get better after you’ve sent them a pile of money. A solid vetting process is what protects your investment and helps you build a supply chain that actually lets you scale.

Your Step-by-Step Sourcing Playbook

Knowing the theory is one thing, but putting it into practice is what separates successful brands from the rest. Finding the right supplier on a bulk buying website can feel like searching for a needle in a haystack. That's why you need a repeatable, structured process.

This five-stage workflow is your playbook. It breaks down the entire journey into clear, manageable steps, taking you from a massive list of potential suppliers to a reliable partner you can build your business on.

Follow this plan to cut through the noise, minimize your risks, and forge the kind of supplier relationships that actually help you scale.

Stage 1: Initial Research and Shortlisting

Your first move is to cast a wide net before slowly reeling it in. The goal here is to identify five to ten potential suppliers for your product. Don't limit yourself to just one type of bulk buying site; explore marketplaces, direct manufacturers, and even liquidators to see what's out there.

At this stage, your job isn't to pick a winner. It's to build a strong list of candidates.

Fire up a simple spreadsheet to keep everything organized. You'll want columns for the supplier's name, website, product specs, listed price, and their Minimum Order Quantity (MOQ). This simple document will be your command center, preventing you from losing track of good prospects and making comparisons a breeze later on.

Stage 2: Professional Outreach and Communication

With a shortlist in hand, it's time to reach out. First impressions matter. Draft a clear and concise introductory email that explains who you are, the product you’re interested in, and your estimated order volume. You want to sound like a serious, professional buyer.

This first email is your chance to ask the questions that websites don't always answer:

- Can you confirm your tiered pricing structure?

- What are your standard payment terms (e.g., 30% upfront, 70% on completion)?

- Are you able to provide quality certifications like ISO 9001?

- What are your typical production lead times?

Pay close attention to how they respond. Are they quick? Professional? Willing to answer everything clearly? Their communication style is often a window into their overall operational standards.

Stage 3: Sample Testing and Quality Validation

This is the most important rule of sourcing: never commit to a large order without seeing the product for yourself. Requesting samples from your top two or three contenders is non-negotiable. A supplier who stands behind their product will have no issue sending samples, though you should expect to cover the cost of the products and shipping.

Once the samples arrive, put them through their paces. Don't just look at them—use them. Test their durability, functionality, and finish. How do they hold up? Compare them side-by-side against each other and your quality benchmarks. This hands-on evidence is infinitely more valuable than a thousand product photos.

This is also the perfect time to get your own operational house in order. If you’re a Shopify merchant, for example, you’ll want to have the right apps and partners ready to handle inventory and fulfillment when your big order lands. Exploring the Shopify Partner Directory can connect you with vetted experts who can help.

Stage 4: Strategic Negotiation

After you've held the product in your hands and confirmed its quality, you can negotiate from a position of strength. Remember, almost everything is on the table—the unit price, payment terms, and even packaging.

A powerful tactic is to frame your initial order as a trial run for a much larger, long-term partnership.

Instead of just haggling over the price of one order, try this approach: "Our first order will be for 1,000 units. However, our projections show a need for 5,000 units over the next six months. Based on that potential volume, what's the absolute best pricing you can offer us?" This shows you're a serious, growth-oriented buyer and gives them a powerful incentive to give you their best terms right away.

Stage 5: Placing Your First Order

Once you've shaken hands on the terms, it’s time to make it official with a purchase order (PO). This document is your contract and should leave no room for interpretation.

Your PO must clearly detail every single aspect of the agreement: exact product specifications, the price you negotiated, quantity, shipping terms (like FOB or EXW), and the delivery timeline. A detailed PO protects both you and the supplier by putting everything in writing.

This kind of disciplined workflow is exactly why the global group buying market—a huge slice of the bulk buying world—has ballooned to an estimated USD 118.97 billion. As detailed in in-depth market analysis on GlobalMarketStatistics.com, this growth is fueled by smart buyers using systematic methods to lock in massive discounts, often slashing 50-70% off retail prices by structuring high-volume purchases.

Using Data to Maximize Your Sourcing Profitability

Smart sourcing decisions aren't made in a vacuum—they're built on cold, hard data. Diving into bulk buying websites without a firm grasp of your numbers is like trying to drive at night with the headlights off. You might be moving, but you're almost guaranteed to hit something expensive. This is where your sourcing strategy meets your bottom line.

When you shift your sourcing from a gut-feel guess to a data-driven operation, you give yourself a huge advantage. The goal is to figure out the financial impact of a bulk purchase before you spend a dime, making sure every inventory choice actively grows your profits.

Modeling Profitability Before You Purchase

A profit dashboard is easily the most powerful tool in your financial toolkit. Think of it as a simulator for your business, letting you see the future financial impact of your sourcing decisions today. Instead of just hoping a bulk order pays off, you can calculate its effect on your margins with real precision.

So, how does this work in the real world? Before you commit to a big order from a supplier, you plug the new, lower cost-per-unit into your dashboard. It instantly crunches the numbers and updates your key metrics, giving you a crystal-clear picture of the potential upside.

This approach lets you answer critical questions right away:

- By how much will this new supplier lower my Cost of Goods Sold (COGS)?

- What will my new profit margin be on every unit I sell?

- How many units do I need to move to hit the break-even point on this inventory investment?

This screenshot from HiveHQ's Profit Dashboard shows how all these metrics come together in one clean, easy-to-read view.

Seeing the data laid out like this turns abstract spreadsheet numbers into a clear, actionable financial forecast for a specific product.

Validating Inventory Decisions with Sales Data

Okay, so modeling proves a product can be profitable, but how do you know it will actually sell? This is where your creator and affiliate marketing data becomes incredibly valuable. When you see strong, consistent performance from specific influencers, that’s a powerful signal that a product has enough momentum to support a larger inventory investment.

Imagine one of your products is constantly flying off the shelves, mostly thanks to a handful of high-performing TikTok creators. Your Creator Tracker shows their videos aren't just getting views; they're driving actual sales. This isn't just a marketing win—it’s a bright green light for your sourcing team.

This data gives you the hard evidence you need to confidently place a much larger bulk order. You're no longer guessing about future sales; you're making an inventory decision backed by proven, repeatable performance from your top affiliate partners.

This strategy is especially powerful right now. The number of bulk buying websites has exploded alongside the e-commerce boom, with over 28 million online stores now operating worldwide—a 2.9% jump from the previous year. This massive market fragmentation makes platforms offering bulk deals even more critical, as they can often slash unit costs by 20-40%. For anyone tracking creator ROI, these numbers should scream opportunity. You can find more online shopping statistics on Optinmonster.com.

Connecting Sourcing to Your Marketing Engine

When you integrate your sourcing decisions with creator performance data, you build a powerful feedback loop. The products that are selling well get the inventory they need to scale, while the underperformers don’t tie up your precious capital. This dynamic approach ensures your cash is always working where it can generate the highest possible return.

For example, you can use sales data to create visual reports of affiliate performance. If you're curious, check out our guide on how to make a heat map to see which creators or regions are driving the most sales. This adds another layer of confidence to your bulk buying decisions and turns your marketing efforts into a direct input for a smarter, more profitable supply chain.

Got Questions About Buying in Bulk? Let's Clear Things Up.

Even when you've done your homework, jumping into the world of bulk buying can feel a little overwhelming. You're bound to have questions. Here are some of the most common ones I hear from other e-commerce sellers, along with some straight-to-the-point answers.

Do I Actually Need a Business License to Buy in Bulk?

This is a big one, and the short answer is: usually, yes. Most legitimate wholesale marketplaces and manufacturers will ask for a business license or reseller’s permit right off the bat. It’s their way of making sure you’re a real business and not just someone trying to snag a consumer deal.

That said, you can sometimes find a workaround. Certain platforms, especially liquidation sites or even some individual sellers on larger marketplaces, might not require one. Just know that without those official credentials, you probably won't get access to the absolute best pricing tiers.

What's a Good Profit Margin to Aim For?

There's no golden rule here, because what’s considered a "good" profit margin can be all over the map depending on your niche. If you’re selling high-volume, everyday items, you might be looking at a tighter margin, maybe around 15-25%. On the other hand, for unique or specialized products, you could easily aim for 50% or even higher.

The most important thing is to get your numbers right. You have to calculate your landed cost—that’s the unit price plus all the shipping, taxes, and import fees. This is the only way to know what your true profit will be. Your margin should be healthy enough to cover all your operating costs and leave enough cash to reinvest in growing the business.

How Do I Handle Shipping for Such Large Orders?

Logistics for bulk orders is a whole different ballgame compared to shipping out individual customer packages. Forget small boxes; we're talking about pallets, freight, and shipping containers.

Here’s what you absolutely need to get right:

- Know Your Incoterms: You'll see terms like FOB (Free On Board) or EXW (Ex Works) on quotes. These aren't just jargon; they define exactly who is responsible for the shipment and when. Make sure you understand them.

- Hire a Freight Forwarder: Don't try to manage international freight yourself. A good freight forwarder is worth their weight in gold. They'll handle everything from booking space on a ship to dealing with customs, making sure your inventory doesn't get stuck at the port.

- Get Shipping Insurance: Seriously, don't skip this. Freight gets lost or damaged more often than you'd think. For a tiny fraction of your inventory's value, insurance protects your entire investment. It’s a no-brainer.

You can negotiate the best unit price in the world, but if you mess up the shipping, your profit margins will vanish. Think of a reliable freight forwarder not as a cost, but as an essential investment in your supply chain.

Making smart, data-driven sourcing decisions is what separates thriving brands from the ones that fizzle out. With HiveHQ, you can take the guesswork out of the equation. Use our Profit Dashboard to see exactly how a bulk purchase will impact your bottom line, and then use the Creator Tracker to see which products are actually selling. Transform your sourcing strategy with HiveHQ today.